Coolant Saving Solutions

As part of Brown & Holmes (Tamworth) Group Ltd, TFS have the sole right to distribute Wogaard products in the UK. Wogaard manufactures coolant-saving devices which collect used coolant from CNC machines and other industrial processes safely and efficiently, ready for reuse.

Founded by Christian and Preben Woergaard, the company was established to explore several ideas the pair had been developing, drawing on their experience in precision engineering and CNC machining.

Their products are most useful for: –

- High Volume CNC Machining – Improving efficiency by even 1% where significant amounts of volume are being produced can equate to £1,000’s in savings, depending on the size of the project. If you work with high volumes in CNC, you need to explore every way to increase efficiency as much as possible –recycling coolant fluid being one of the best examples.

- Metal Machining – As you machine various metal parts, you’ll find that different parts inside the machine begin to wear. Ensuring that everything possible is done to limit the potential impact your machine may experience in this regard is essential to maintaining profitability. Recycling coolant is one of the more effective ways to ensure this process happens smoothly.

- Grinding/Polishing – Maintaining high precision and fidelity is essential to ensuring the quality of the wares you produce. One of the most crucial elements of this process is ensuring that you use the correct amount of coolant to prevent your machine tools from creating unnecessary defects.

—

Brown & Holmes own the rights to distribute Wogaard products in the UK, with Total Filtration Solutions Ltd. being spun off as a subsidiary to focus on efficiencies etc: –

Products

A simple solution with a significant impact! Specifically designed for CNC machines, Wogaard coolant savers are easy to install.

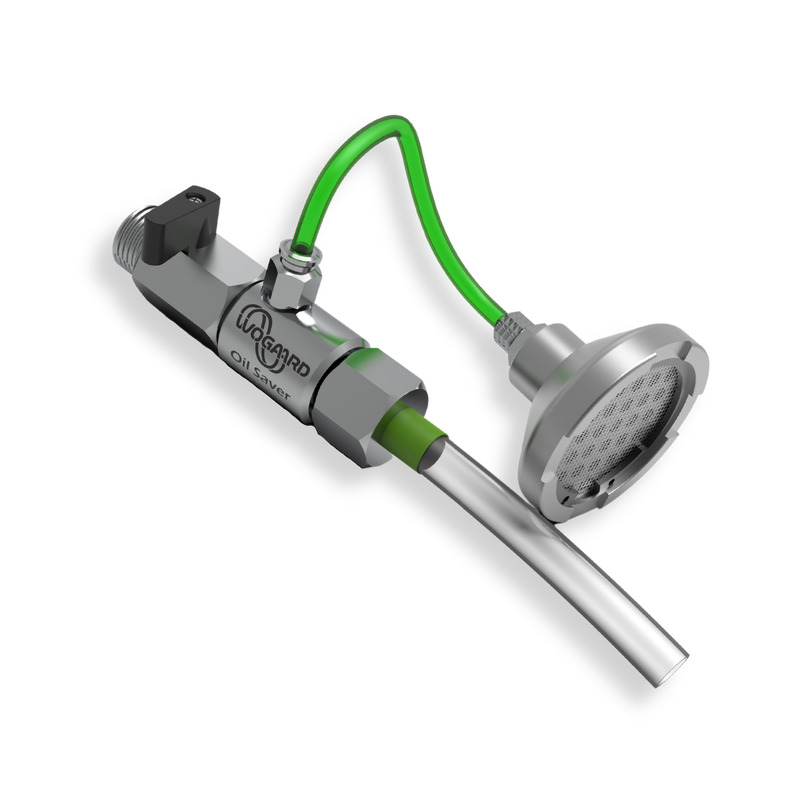

Oil Saver

Designed for neat oil applications and possible to install in a wide range of CNC sliding head machines (Swiss style lathe), the Oil Saver will allow you to reduce, reuse and recycle the neat oil that is dragged out into the swarf bins from the conveyor.

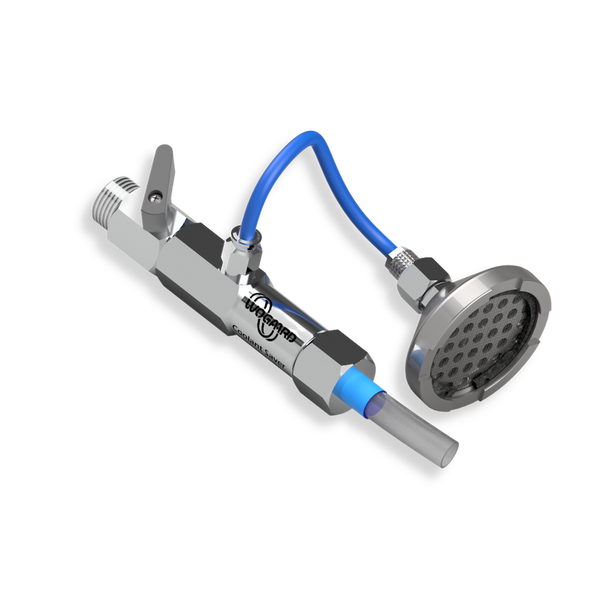

Coolant Saver

Designed for soluble coolant applications and possible to install in a wide range of CNC machines, the Coolant Saver will allow you to reduce, reuse and recycle the coolant that is dragged out into the swarf bins from the conveyor.