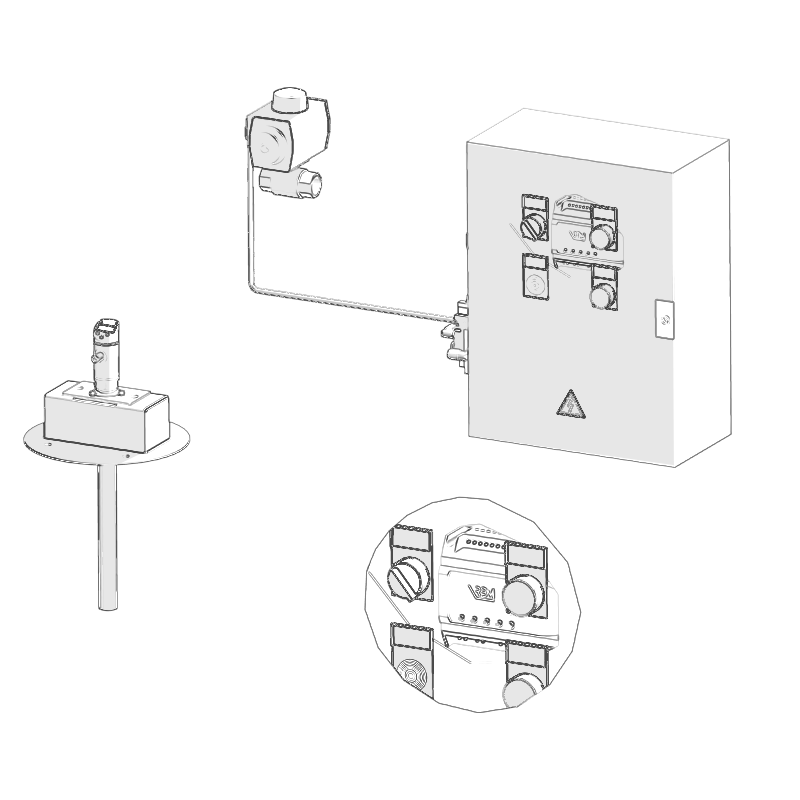

RA-IN Independent automatic coolant top-up

The need to make the machine tools work on unmanned shifts made it necessary to develop a solution to restore the correct level of coolant in the machine tool tanks: the independent automatic coolant top-up. This solution allows the correct level in the tanks to be maintained without the risk of cutting fluid dispersion. The main…

Reconstruction of the machine tool tank

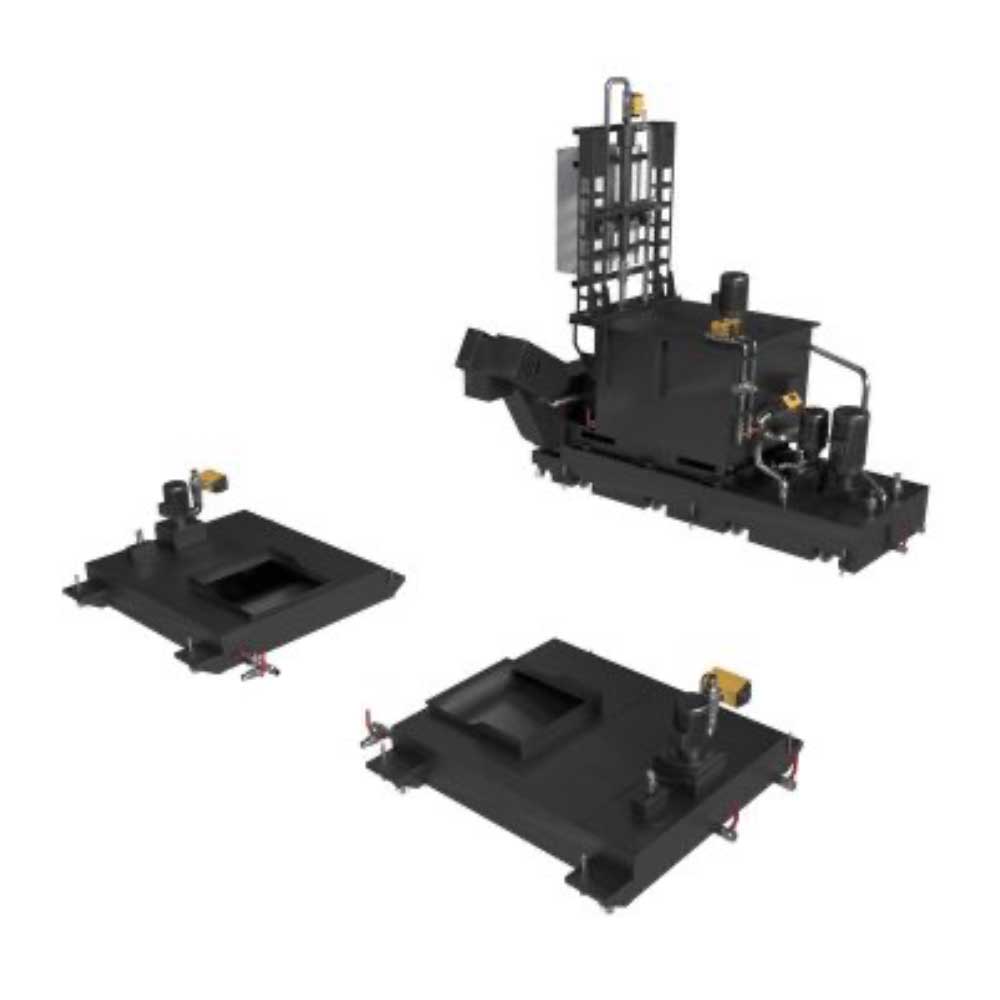

The reconstruction of the machine tool tank is one of the possible options available for optimizing the integration of all A-I chip conveyors, studying a suitable movement of liquids aimed at capturing and extracting the maximum quantity of sludge present in the tank. This option must be evaluated specifically on the machine tool where RBM solutions will be…

Blowing-carpet Blade

The blowing-carpet blade is designed to prevent that light chips made of plastic material, composite materials or light alloys stick onto the metal carpet and are taken back to the tank, thus creating an abnormal accumulation in the coolant’s tank or inside the rotofilter. The blowing-carpet blade facilitates chip removal from the carpet, making it…

Wash Gun

The wash gun has an anchoring support to the machine tool, which allows the pump to be activated as soon as the gun is lifted from its own support. The pump stops automatically after an interval set by the management PLC.

Automatic Sludge Extractor

The automatic sludge extractor is applied when machine tools work mainly cast iron or other materials that produce dust. It extracts and drains the sludge separated from the Filstar unit into a special container.

Sludge Settling Container

The forced sludge settling container is applied when machine tools work cast iron for 35% of their total hours. It is applicable to all IFDR models.

Roto-star

ROTO-STAR is the integration of a part of the IFDR system on the A-I conveyor. With ROTO-STAR the rotofilter’s drum is kept clean and the blockage of the nozzles during backwash is avoided, in addition to carrying out continuous filtering at 20 µm of the cutting fluid present in the tank of the machine tool.

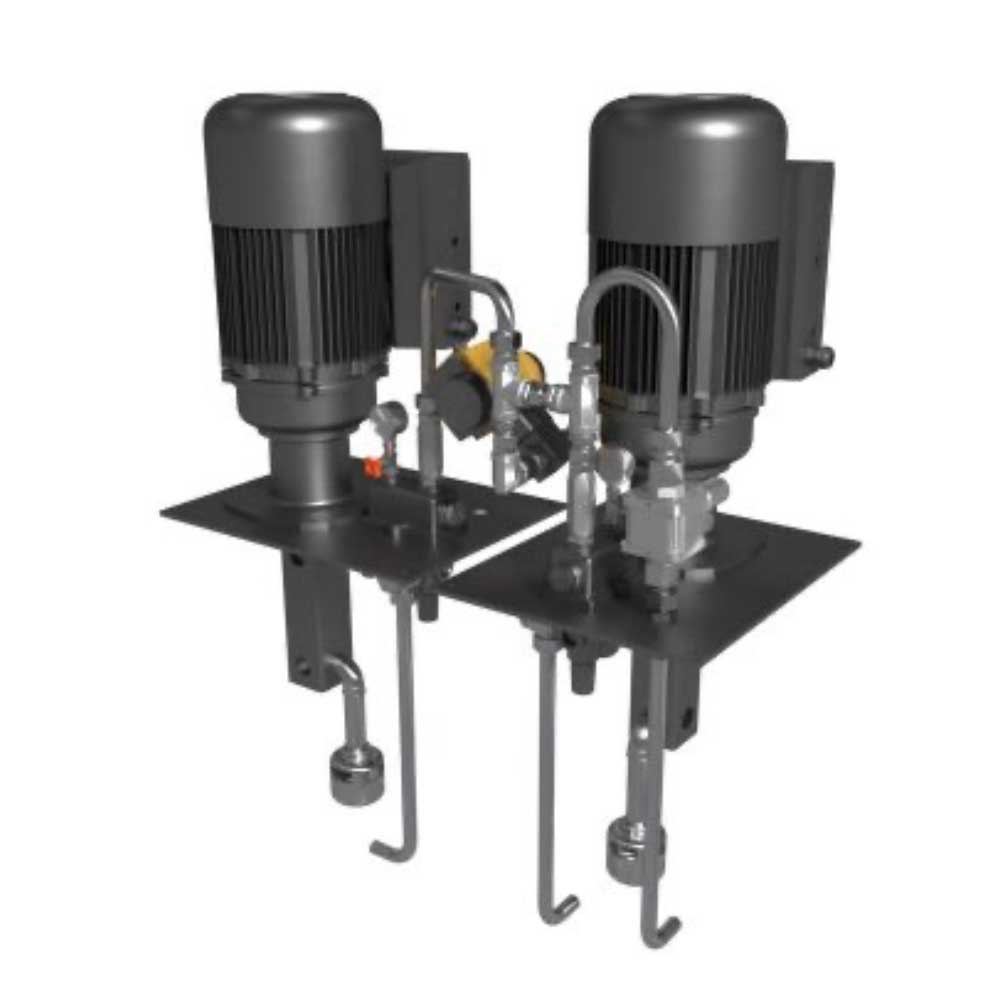

Duplex

The DUPLEX optimizes energy consumption, allowing a wide range of combinations of pressure/flow rate relationship. It is available in two models: The main features are: DUPLEX represents a radical change in the culture of high-pressure machining and allows optimization of tool use, reduction of cycle time, the extension of tool life and consequent reduction of waste.

Chiller

The chiller for coolant’s temperature control can be matched to all RBM fine filtration systems, both CORE and IFDR models. It has been designed to work in a workshop environment, and its advantages are: