IFDR Coolant Filtration Systems – What to know and how they work

Striation is a significant problem for precision manufacturers due to the way in which it can impact the integrity of the end products.

The causes of this are often overlooked, leading to higher reject rates and loss of efficiency. It’s therefore important to consider ways you can avoid it becoming an issue if you have the means to do so.

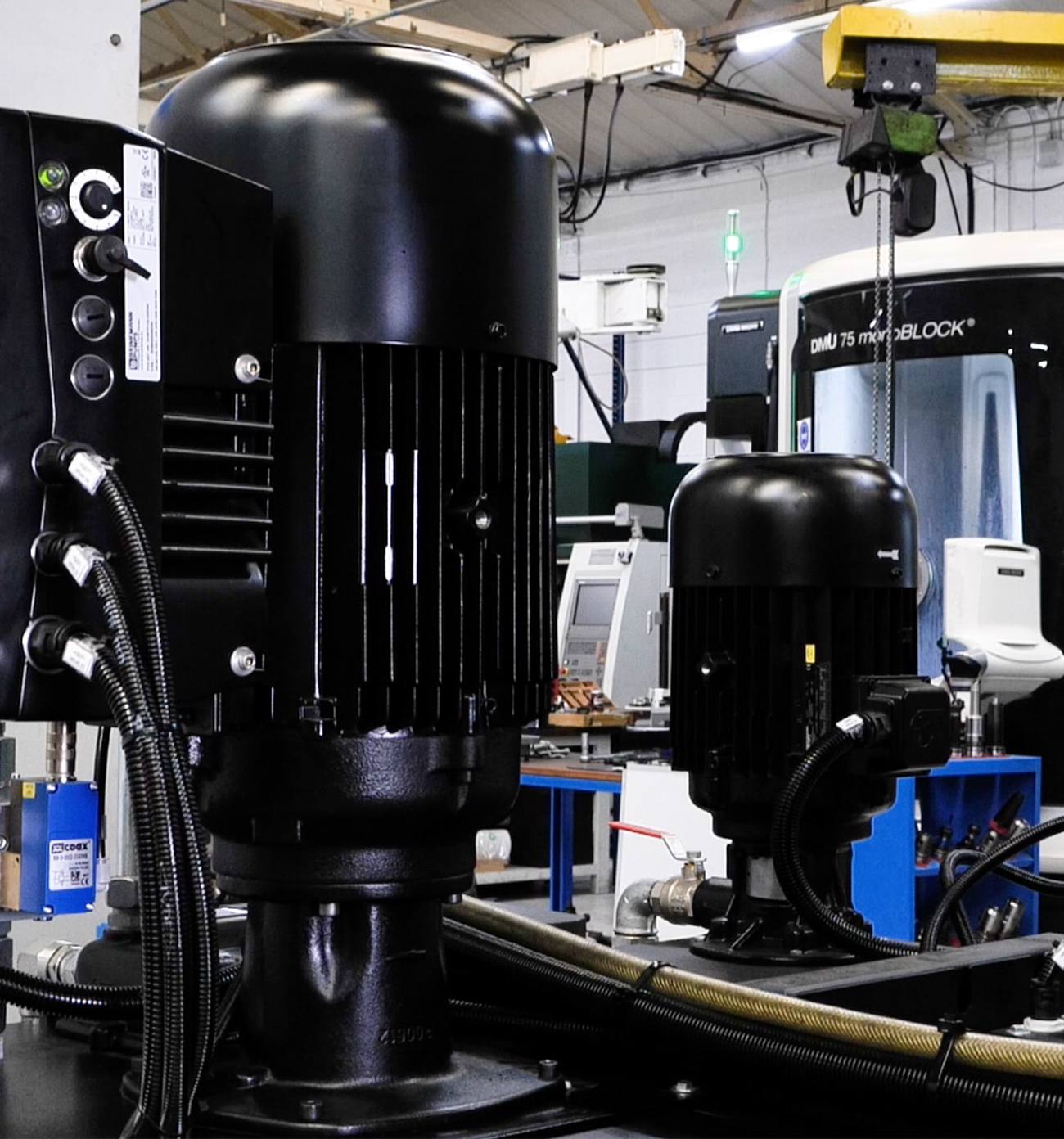

Intelligent Fluid Delivery & Recycling (IFDR) systems are able to aid with this process by providing the means to filter the CNC coolant fluid used in the machining process: –

The products work to provide sub micron filtration for any contaminants inside the CNC coolant.

They take the recycled coolant, process it through a series of filters and then pump it back to the CNC machine, allowing it to re-use the coolant without any risk of contaminants.

TotalFiltrationSolutions work with a company called RBM to provide the means for our clients to filter the coolant on their CNC machines: –

RBM are an Italian company who specialise in liquid filtration and management.

Their range of IFDR machines is world leading in that they don’t use paper media to filter coolant. This allows for significant improvements to efficiency and lower maintenance costs.

—

IFDR works as follows: –

A central pump is attached to the CNC machine and extracts any coolant from the system when in operation.

The pump pushes the coolant through a series of filters to remove contaminants from the liquid down to the submicron level. As mentioned above, this ensures that the coolant remains as pure as possible, limiting the risk of abrasion when machining.

The RBM IFDR range manages coolant flows of 300, 500, 800 and 1000 litres. If larger volume handling is required or, as in a recent case where a single system needed to work with 25 machine tools, a bespoke solution can be provided.

If you are interested in exploring any options to help improve the performance, efficiency and longevity of your CNC machine coolant, you should consider contacting us to discuss your potential options.