Air & coolant filtration specialists

Highly efficient, sustainable solutions for today’s manufacturers. Extending machine life and maintaining your HSE obligations with a more efficient, safe working environment.

Essential CNC coolant and mist filtration

As a leader in precision engineering, Brown & Holmes (Tamworth) Group Ltd has been providing air filtration solutions to its clients for some time. Forming Total Filtration Solutions as a specialist subsidiary was the natural next step.

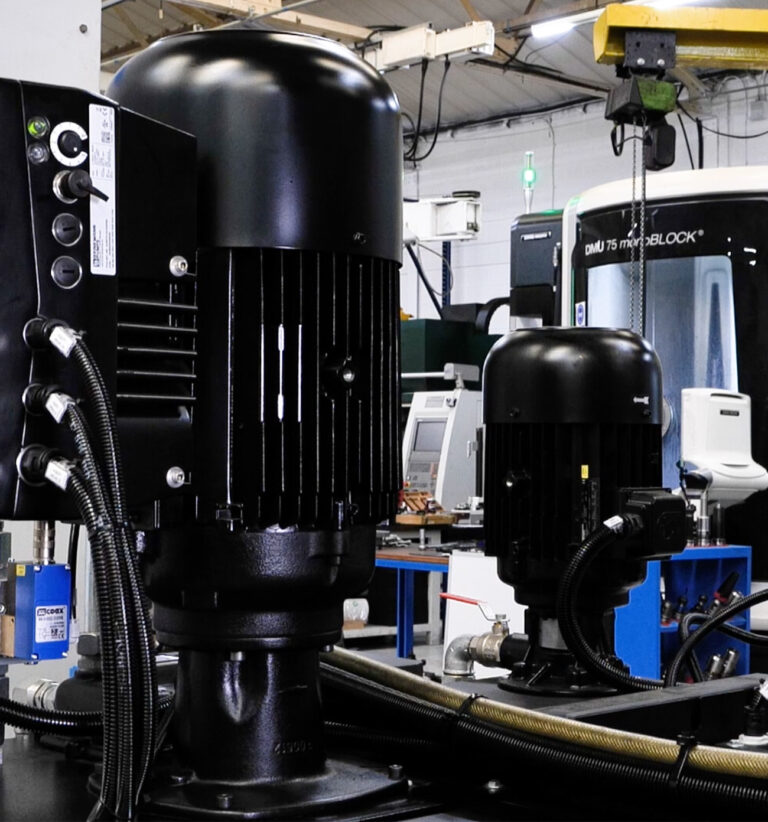

The increased use of 3- and 5-axis CNC machines enables the production of mass-produced parts with low levels of deviation, while providing engineers with greater flexibility in precision and material selection. With accuracy, quality and reliability in the balance, maintaining CNC machines has never been more critical; filtration plays a key role in this process.

Total Filtration Solutions Ltd aims to provide effective and innovative solutions, helping them reduce waste, maintain tooling quality, and extend the life of their machines.

The importance of filtration for CNC machining

Maintaining CNC machine precision, longevity and reducing maintenance costs are key reasons why filtration should be an integral part of your manufacturing process.

In continuous or high-volume machining, the precision of tooling, component quality, and machine health directly impacts production costs and profitability. Maintaining high fidelity in these areas ensures consistent output, reduces waste and downtime, and ultimately lowers operating expenses.

Filtering the coolant, or the air and fumes of the machine, is one of several ways this can be achieved. Depending on the solution used, efficiency improvements result in machines that can produce at a very high quality for longer:

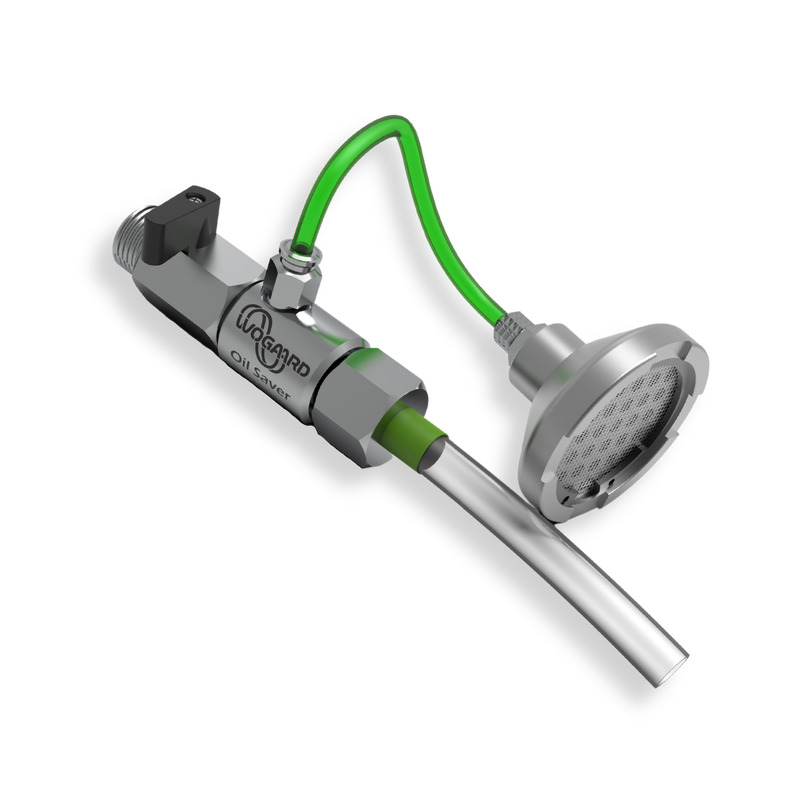

- Coolant Filtration – When a CNC machine operates, liquid is sometimes used to cool the tools that are performing the cutting. Our systems collect coolant after it is sprayed, allowing it to be reused as needed. Sometimes, the collected coolant may contain metallic particles. These particles can be filtered out before being used again, ensuring they don’t damage the part being manufactured

- The filtering of air-based contaminants (and removing any submicron particles) created during the machining process is essential. Air filtration is as much about ensuring the health and well-being of machine operators by improving indoor air quality, as it is about protecting your manufactured parts from contamination and maintaining the life of your machines.

Investing in filtration systems when producing large volumes will not only help with compliance with HSE, creating a safer and more welcoming environment for your operators, but will also ensure higher precision and lower defects in your drilling processes.

Product Categories

If CNC forms part of your manufacturing process, either on-premises or as part of a wider supply chain, we can assess and recommend the right solution for you.

Updates & Case Studies

If CNC forms part of your manufacturing process, either on-premises or part of a wider supply chain, maintaining the machines will contribute to any cost savings you may be able to achieve.